Sentrifugale Desulfuration Pump yn macht plant

Dt-searje Fgd Gypsum Slurry Pumpis in inkeld poadium, ien sifers horizontale sintrifugumpomp. Fral brûkt as de sirkulearjende pomp foar absorberjende toer yn FGD-systeem. It hat de foardielen fan brede berikskataciteit, hege effisjinsje, bettere enerzjybesparjende ens binne ûntworpen mei de CFD-floeistof simulearre analysetechnology om te soargjen dat syn heech-effisjinsje-operaasje is. DT-searje Fgd Slurry Pump is optimaal Pump-type foar it ferfier fan gips slurry, kalmerende slurry as oare abrasive en korrosyf medium yn thermyske krêftplants.

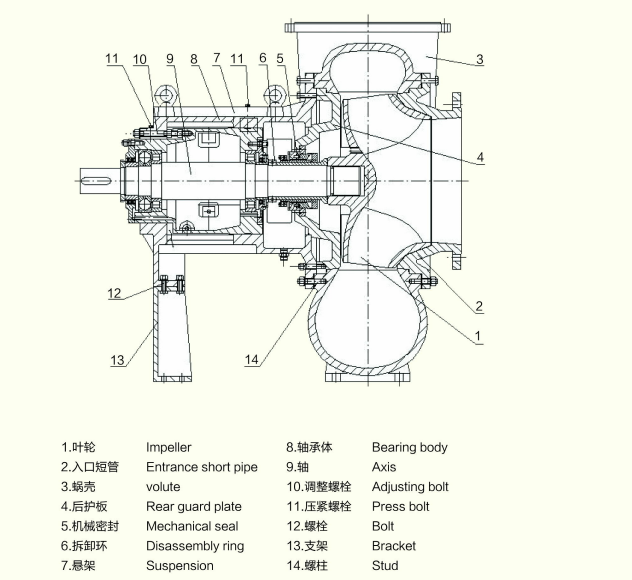

- DT-searje desulfurisaasjepompstruktuer

- Dt desulfurisaasjepomp prestaasjesgegevens

| Model | Max Powerpw | Capacitym3 / H | Haadm | Speedr / min | Npshm | Tastien maxparticle mm | Pump WeightKg |

| 800DT-A90 | 900 | 3142-9700 | 6-28.7 | 300-592 | 2 | 181 | 5900 |

| 700DT-A84 | 630 | 2157-7360 | 5.2-24.5 | 300-591 | 2 | 168 | 5420 |

| 600DT-A82 | 500 | 1664-5600 | 5.2-27.8 | 300-595 | 2.2 | 152 | 4900 |

| 500DT-A85 | 400 | 1036-4080 | 5,7-26.8 | 300-591 | 3.1 | 135 | 4500 |

| 350DT-A78 | 500 | 720-2865 | 11.6-51.1 | 400-740 | 3,5 | 104 | 3700 |

| 300DT-A60 | 400 | 580-2403 | 8.9-53.1 | 490-989 | 4.3 | 96 | 2790 |

| 200DT-B45 | 90 | 138-645 | 5,7-31.0 | 490-990 | 2 | 51 | 1750 |

| 100DT-A50 | 90 | 62-279 | 9.3-44.6 | 490-980 | 2.1 | 30 | 1470 |

| 100DT-A35 | 75 | 77-323 | 8.8-45.9 | 700-1480 | 1.9 | 42 | 550 |

| 65DT-A40 | 55 | 34-159 | 12.2-63.2 | 700-1480 | 2.1 | 16 | 490 |

| 50DT-A30 | 18.5 | 16-78 | 6 6.1-36.3 | 700-1460 | 0.8 | 16 | 210 |

- Dt desulfurisaasjepompEigenskip

Hege effisjinsje, enerzjybesparring, wear ferset, anty-korrosive, leech lûd en vibraasje,

Stabyl rinnende betroubere operaasje test strikt

Lange servicetiid handich om te reparearjen

- Dt desulfurisaasje pompeapplikaasje Foarbyld

Wiid besteglein yn thermyske stroomgewearde, aluminium smelten en ferfine en ferfine yndustry-desfolgewaasje-systeem dat kalkstien as gips slurry ferfiert.

- Desulfurisaasjepomppakket en ferstjoeren

Foar mear ynformaasje oer ús desulfuration Pump, nim dan kontakt mei ús op.

Email: rita@ruitepump.com

Whatsapp / wechat: +8619933139867

Th CantileVere, horizontaal, sintrifugale slurrypomp materiaal:

| Materiaal koade | Materiaal beskriuwing | Applikaasjekomponinten |

| A05 | 23% -30% cr wyt izer | Impeller, liners, Expeller, Expeller Ring, stuffing Box, Throatbush, Framplate Liner ynfoegje |

| A07 | 14% -18% cr wyt izer | Impeller, liners |

| A49 | 27% -29% CR Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion ferset wyt izer | Impeller, liners |

| R55 | Natuerlik rubber | Impeller, liners |

| R33 | Natuerlik rubber | Impeller, liners |

| R26 | Natuerlik rubber | Impeller, liners |

| R08 | Natuerlik rubber | Impeller, liners |

| U01 | Polyurethan | Impeller, liners |

| G01 | Grize izer | Frame plaat, coverplaat, Útpraat, Expeller Ring, Bearing House, Base |

| D21 | DUCTILE IEURN | Framplate, coverplaat, Bearing House, Base |

| E05 | Koalstofstiel | Skacht |

| C21 | Roestvrij stiel, 4CRA13 | SHAFT SLEEVE, LANTRION RING, Lantaarne beheinder, halsring, klierbolke |

| C22 | Rainfrij stiel, 304ss | SHAFT SLEEVE, LANTRION RING, Lantaarne beheinder, halsring, klierbolke |

| C23 | Rainfrij stiel, 316ss | SHAFT SLEEVE, LANTRION RING, Lantaarne beheinder, halsring, klierbolke |

| S21 | Butyl rubber | Joint ringen, mienskiplike seals |

| S01 | EPDM-rubber | Joint ringen, mienskiplike seals |

| S10 | Nitrile | Joint ringen, mienskiplike seals |

| S31 | Hypalon | Impeller, liners, Expeller Ring, Expeller, joint ringen, joint seals |

| S44 / K S42 | Neoprene | Impeller, liners, joint ringen, mienskiplike seals |

| S50 | VITON | Joint ringen, mienskiplike seals |